Gantry Pick & Place Packers Company in Dubai

Gantry Pick & Place Packers Company in Dubai, UAE

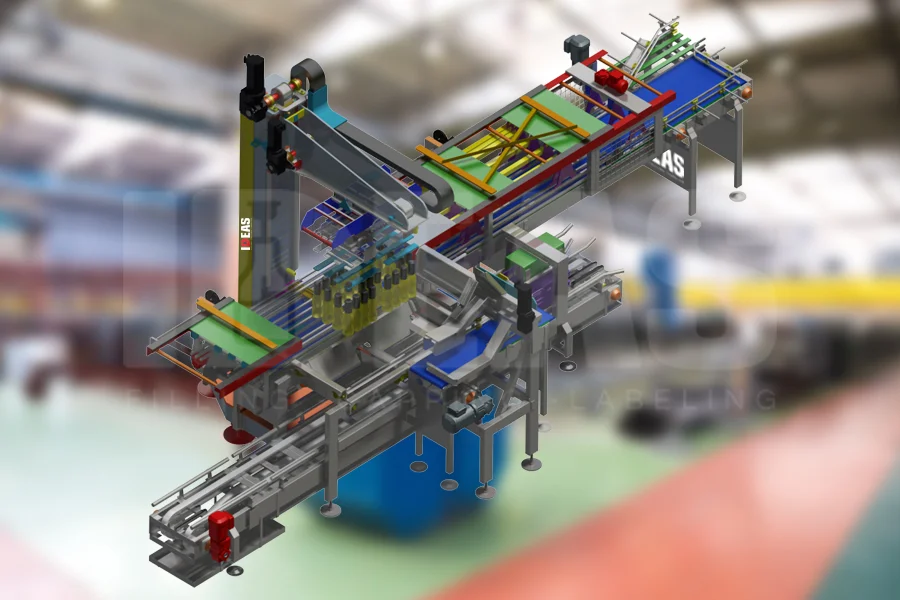

Gantry Pick & Place Packers offer an efficient, reliable solution for automating material handling processes. These advanced systems handle a variety of tasks, such as precise product placement, packaging, and sorting, with speed and accuracy. Designed for flexibility, they can adapt to different product types and sizes, improving productivity across various industries. With user-friendly interfaces, these packers are easy to integrate into existing setups, saving time and reducing manual labour. Their durability and low maintenance requirements ensure long-lasting performance. By choosing Gantry Pick & Place Packers, businesses can optimize their operations and achieve greater operational efficiency with minimal downtime.

8 Key Factors for Selecting the Ideal Gantry Pick & Place Packers to Enhance Operational Productivity?

Quality & Durability

Investing in high-quality items means opting for durability, ensuring a long lifespan without compromising the functionality or aesthetics of the product.

Technology & Innovation

Technology continues to evolve, and with it, innovation brings fresh perspectives and game-changing solutions to modern challenges.

Solutions & Flexibility

The key to our approach lies in delivering solutions that offer both adaptability and scalability, ensuring success in dynamic environments.

Efficiency & Speed

Combining speed and efficiency leads to optimized outcomes, allowing us to deliver results quickly while minimizing waste and resources.

Design & Maintenance

Great design is only the beginning our maintenance ensures that every feature remains operational and effective, providing lasting performance.

After-Sales Support

Offering proactive after-sales support, we ensure that you can resolve any issues quickly and continue enjoying your purchase with confidence.

Safety & Standards

Safety is our top priority, and we ensure that our products consistently meet or exceed the highest industry standards for performance and protection.

Competitive Pricing

Pricing is carefully set to be competitive, ensuring that customers receive products that exceed expectations at affordable costs.

Frequently Asked Questions (FAQ)

What is a Gantry Pick and Place Packer?

What industries use Gantry Pick and Place Packers?

How does a Gantry Pick and Place Packer work?

What are the main advantages of using Gantry Pick and Place Packers?

Can Gantry Pick and Place Packers handle delicate or fragile items?

What types of products can be packed using Gantry Pick and Place Packers?

Are Gantry Pick and Place Packers customizable?

These systems can be customized to meet specific production requirements, such as adjusting the speed, type of gripper, or the layout of the production line. This makes them suitable for various industries and tasks.

What is the typical cost of a Gantry Pick and Place Packer?

The cost of a Gantry Pick and Place Packer depends on its size, capabilities, and customization. Depending on the complexity and features required, prices can range from tens of thousands to several hundred thousand dollars.

How easy is it to integrate a Gantry Pick and Place Packer into an existing production line?

Gantry Pick and Place Packers are generally designed to integrate easily with existing production lines, with minimal disruption. Integration involves connecting the system to conveyors, sensors, and existing packing stations and may require some customization.

What maintenance is required for Gantry Pick and Place Packers?

Regular maintenance includes checking the robotic arm, ensuring that the grippers or suction cups are functioning correctly, cleaning sensors and cameras, and updating software. Preventive maintenance helps reduce downtime and ensure optimal performance over time.