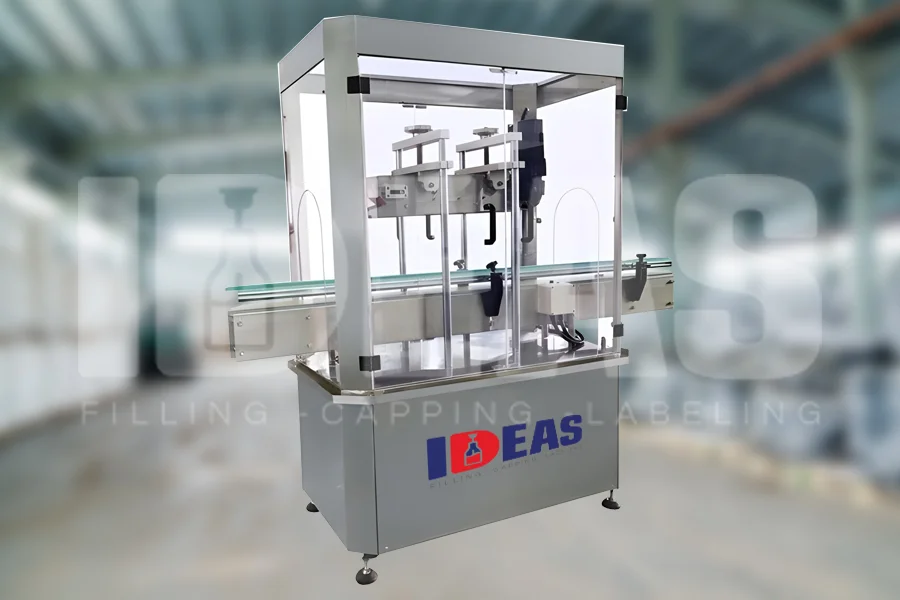

Snap-On Capping Machine Company in Dubai

Snap-On Capping Machine Company in Dubai, UAE

Based in Dubai’s lubricant industry hub, our company offers cutting-edge snap-on capping machines designed for reliable and precise packaging. These machines securely cap lubricant containers of various shapes and sizes, ensuring product protection and quality. Engineered for durability and efficiency, our capping systems provide high-speed performance and seamless operation, reducing downtime and improving productivity. Easy to operate and maintain, they are tailored to meet the unique requirements of lubricant businesses. With customizable options and advanced features, our snap-on capping machines deliver consistent results, helping you optimize your packaging process and achieve cost-effective, high-quality production standards.

8 Key Aspects to Examine Before Choosing the Best Snap-On Capping Machine for Your Business?

Evaluate machine speed, compatibility, precision, durability, user-friendliness, customization options, maintenance requirements, and cost-effectiveness to select the best snap-on capping machine tailored to your business’s unique needs.

Quality & Durability

Long-lasting and reliable machines maintain consistent output with minimal upkeep, enhancing productivity and ensuring smooth operations over time.

Technology & Innovation

Technology and innovation drive transformation, creating new opportunities, enhancing systems, and improving processes for greater efficiency and future growth.

Solutions & Flexibility

Adaptable solutions and flexibility enable businesses to respond swiftly to evolving demands and obstacles, ensuring growth and continuous success.

Efficiency & Speed

Efficiency and speed allow businesses to optimize processes, cut down on waste, achieve quicker outcomes, and enhance overall productivity.

Design & Maintenance

Design and maintenance guarantee that products are visually attractive, durable, and practical, ensuring long-term reliability and optimal functionality.

After-Sales Support

After-sales support assists customers post-purchase, ensuring their satisfaction by addressing concerns, solving issues, and enhancing overall experience.

Safety & Standards

Safety protocols and standards guarantee that products and services adhere to necessary quality guidelines and regulatory requirements, ensuring reliability and compliance.

Competitive Pricing

Competitive pricing offers great value, staying in line with market demands, and helping businesses attract loyal customers while boosting sales.

Frequently Asked Questions (FAQ)

The Snap-On Capping Machine efficiently applies snap-on caps to containers, ensuring secure and consistent sealing for various products. It enhances production speed and reliability, making it ideal for high-volume operations.

What is a Snap-On Capping Machine?

A Snap-On Capping Machine is an automated system designed to securely attach snap-on caps to containers, ensuring proper sealing for various products.

How does a Snap-On Capping Machine work?

The machine places the snap-on cap onto the container and applies pressure to securely seal the cap, providing a tight closure without requiring additional torque.

What types of products can be sealed using a Snap-On Capping Machine?

Snap-On Capping Machines are versatile and can be used for sealing products in industries like food and beverages, cosmetics, pharmaceuticals, and household items.

What are the key benefits of a Snap-On Capping Machine?

- Efficiency: Automates the capping process, increasing production speed.

- Consistency: Provides uniform sealing for all containers.

- Cost-Effective: Reduces labour costs and ensures minimal waste.

Can the Snap-On Capping Machine handle different cap sizes?

many Snap-On Capping Machines are adjustable and can accommodate different cap sizes, ensuring flexibility in production.

Is the Snap-On Capping Machine easy to maintain?

Snap-On Capping Machines are designed for easy maintenance. They require routine cleaning, lubrication, and occasional part replacements for optimal performance.

What industries use Snap-On Capping Machines?

Snap-On Capping Machines are commonly used in industries such as food and beverages, pharmaceuticals, cosmetics, and cleaning products to efficiently package products.

How do I choose the right Snap-On Capping Machine?

When choosing the appropriate machine for your needs, consider factors such as production speed, cap size, automation level, and the type of product being packaged.

What is the typical cost of a Snap-On Capping Machine?

The cost varies based on factors like machine capacity, features, and customization. Basic models start at a lower price point, while advanced systems can be more expensive.

Can the Snap-On Capping Machine be used for both glass and plastic containers?

Snap-On Capping Machines are suitable for sealing both glass and plastic containers, and they can be adjusted to accommodate different materials and sizes.