Filling Machines Company in Dubai

Filling Machines Company in Dubai, UAE

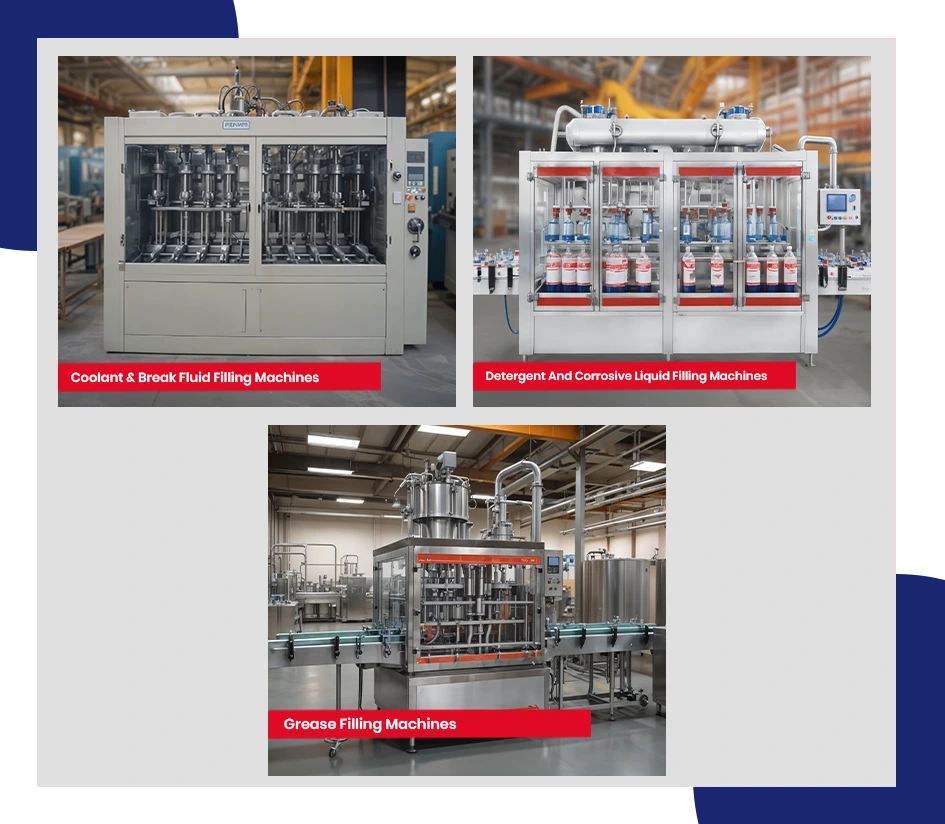

Ideas Packaging is a leading filling machines company in Dubai, boasting over 25 years of extensive global experience in versatile liquid packaging systems and solutions. We specialize in coolant and brake fluid filling machines, detergent and corrosive liquid filling machines, and grease filling machines, ensuring high quality, reliability, and efficiency across various industries. Our expertise enables us to offer customized solutions tailored to meet the specific needs of our clients.

We are dedicated to helping businesses streamline their operations and enhance productivity through innovative packaging technologies. Whether you are embarking on a new project or looking to upgrade your existing systems, Ideas Packaging is here to support you with tailored solutions and exceptional service.

Types of filling machines we supply in the UAE

Gravity Filling Machines

Ideal for thin, free-flowing liquids (e.g., water, wine)

Piston Filling Machines

Best for thick, viscous products (e.g., creams, sauces)

Overflow Filling Machines

Ensures consistent fill levels for foam liquids (e.g., shampoos, cleaners)

Vacuum Filling Machines

Works well with glass containers used for liquids (e.g., perfumes, solvents

Pump Filling Machines

Suitable for a wide range of liquids (e.g., oils, lotions)

Net Weight Filling Machines

Fills based on the product's weight, often used for bulk products (e.g., detergents, chemicals)

Auger Filling Machines

Used for powders and granules (e.g., flour, spices)

Flow Meter Filling Machines

Measures the flow to ensure accurate volume, suitable for high-value liquids (e.g.,pharmaceuticals, oils)

Rotary Filling Machines

Suitable for high-speed production, it is often used in beverage industries.

Aseptic Filling Machines

Designed for sterile products (e.g., dairy, pharmaceutical liquids)

Advantages of Our Tailor-Made Filling Machines

Experience the advantages of our custom-made filling machines, designed to suit your needs perfectly. These machines enhance efficiency with precise, consistent filling, reducing waste and operational costs. Tailored to fit your specific requirements, they integrate seamlessly into your production line, boosting overall productivity. Our machines are built for durability and reliability, ensuring long-lasting performance with minimal downtime. Additionally, we offer dedicated support and maintenance to keep your equipment running smoothly. Choose our custom-filling solutions to elevate your operations with advanced technology and exceptional service.

Top Filling Machine Suppliers in UAE

Ideas Packaging is a trusted name among top filling machine suppliers in the UAE, providing high-quality filling machines for liquids, pastes, powders, and granules. Our Filling Machine solutions cater to a wide range of industries, including chemical, food, beverages, cosmetics, and pharmaceuticals. We offer advanced, stainless-steel machines with precision control to ensure efficient, hygienic, and reliable filling. Whether you need automatic, semi-automatic, or fully customised machines, Ideas Packaging delivers fast, local support and tailored solutions. With a focus on performance, compliance, and customer satisfaction, we help streamline your production line from start to finish.

Coolant & Break Fluid Filling Machine

Enhance your production with our high-performance coolant and brake fluid filling machines. Designed for precision and speed, they ensure accurate, waste-free filling, improving efficiency and reliability in automotive and industrial processes. Streamline your operations with state-of-the-art technology.

Detergent And Corrosive Liquid Filling Machine

Upgrade your operations with our state-of-the-art detergent and corrosive liquid filling machines. These machines are designed for precision and durability. They can effortlessly handle harsh chemicals, ensuring accurate and reliable filling. Using these machines can improve your production line’s safety and efficiency.

Grease Filling Machine

Upgrade your production with our advanced grease-filling machines. Engineered for precision and durability, they ensure consistent filling of thick greases, enhancing efficiency and dependability. Experience unparalleled performance with our innovative technology.

Carbonated Filling Machine (CSD)

Take your production to the next level with our easy-to-use Carbonated Filling Machine (CSD). This machine is made to be super accurate and robust, even with tricky carbonated drinks. It fills every bottle just right, making your production line safer and more efficient. This machine helps stop spills and mistakes so your factory can run smoother and faster.

Juice Filling Machine

Elevate your manufacturing process with our easy-to-operate Juice Filling Machine. This system is built for maximum accuracy and reliability, even when handling complex fluids and beverages. It ensures that each bottle is filled precisely, enhancing the safety and productivity of your assembly line. This advanced equipment will reduce spills and errors, helping your operation run more smoothly and efficiently.

Lubricant Filling Machine

Our Lubricant Filling Machines offer precision and efficiency, specially designed to handle various types of lubricants. With advanced technology, these machines ensure accurate filling, reducing wastage and enhancing productivity. Suitable for a range of industries, they are easy to maintain and deliver reliable, high-quality results for optimal performance.

Leading Global Supplier of Filling Machines

Setup and After-Sales Service

At Ideas Packaging and Machinery, we ensure that the setup of your filling machines is quick and hassle-free. Our skilled team manages everything from installation to testing, ensuring your equipment operates flawlessly. After setup, we offer dependable after-sales service to keep your machines running smoothly. This includes regular maintenance, prompt troubleshooting, and speedy repairs to reduce downtime. We are dedicated to supporting your success with efficient and friendly service. Choose Ideas Packaging and Machinery for expert setup and continuous support that keeps your operations running efficiently and without interruptions.

What are the most important factors you consider when choosing packaging machinery for your business?

At Ideas Packaging Machinery LLC, we recognize the crucial impact that packaging machines have on the efficiency of your business operations. We are dedicated to providing exceptional packaging solutions that meet and surpass your expectations.

Quality & Durability

Our machines are designed for consistent performance, employing premium materials and precise engineering to reduce downtime and enhance the durability of your investment.

Technology & Innovation

Stay at the forefront with our Next Generation Machines , as Ideas Packaging harnesses the latest technology to enhance efficiency, productivity, and ongoing advancement.

Solutions & Flexibility

We provide custom machines tailored to your packaging needs, accommodating various products while ensuring full production control.

Efficiency & Speed

Our custom machines efficiently handle high-volume production, delivering quick, quality packaging to maximize output.

Design & Maintenance

Our machines provide simple controls and low maintenance, ensuring smooth and reliable production.

After-Sales Support

At Ideas Packaging, we ensure customer satisfaction by providing prompt after-sales support, spare parts, technical assistance, and routine maintenance.

Safety & Standards

At Ideas Packaging, we prioritize customer satisfaction with fast after-sales support, while our machines ensure safety and full compliance with industry standards.

Competitive Pricing

We offer high quality machines at competitive prices, delivering excellent value by lowering long-term costs and enhancing production efficiency.

10 Benefits of Filling Machines

Enhanced Efficiency

Our machines streamline production flow, enable faster, more consistent packaging, and significantly increase output.

Cost Reduction

Automation lowers labour costs, reduces packaging errors through precise and consistent packaging, and minimizes waste, saving businesses money.

Customizable Solutions

Our machines are not one-size-fits-all. They are tailored to fit your unique production needs, ensuring a perfect fit for your specific product types and processes.

Durability and Reliability

Built with best quality materials and genuine parts, our machines ensure long-term use, reducing downtime and maintenance costs.

Precision and Consistency

Every machine provides uniform packaging, enhancing product quality and maintaining brand consistency.

Scalability

As your business expands, our packaging solutions can quickly scale, increasing production capacity without delays.

Compliance

All our machines meet global standards like FDA, CE, and GMP, ensuring market compliance.

Environmentally Friendly

Our machines feature energy-efficient designs, such as automated power-saving modes and low-energy consumption motors, helping businesses reduce their environmental impact.

Support and Training

We offer ongoing support and training to ensure your team operates the machines efficiently and resolves issues quickly.

Advanced Technology

Our cutting-edge solutions, including automation and robotics, future-proof your packaging operations and keep you competitive globally.

10 Key Things to Consider Before Buying Filling Machines for Your Production Line.

If you are setting up a production line or upgrading your existing one, choosing the right filling machine is a big decision. Filling machines are essential for packaging products like liquids, powders, or creams. They help ensure that your product is filled into containers quickly and accurately. But how do you know which filling machine is the best for your business?

Frequently Asked Questions (FAQ)

Please explore the most common questions about our filling machines: types, industries served, customization, accuracy, maintenance, safety features, and support for food, beverages, oils, cosmetics, and more.

What types of filling machines do you offer?

We provide machines for liquid, paste, powder, and granular products.

Can your machines handle different liquids?

Our machines can fill water, oils, juices, sauces, and more.

Are your filling machines suitable for food and beverages?

We offer machines designed for food, drinks, and other industries like cosmetics and pharmaceuticals.

What’s the difference between manual, semi-automatic, and fully automatic filling machines?

Manual machines require complete human control, semi-automatic machines need some assistance, and fully automatic machines work without human intervention.

Can I customize a filling machine for my product?

Yes, we provide customized solutions based on your product and packaging needs.

How accurate are your filling machines?

Our machines are highly accurate, reducing product waste and ensuring consistent fills.

What maintenance do filling machines need?

Regular cleaning, part checks, and lubrication are needed to keep the machines running smoothly.

How long does installation take?

Installation time varies by machine type, but we offer support to ensure a quick setup.

Do you offer technical support if the machine breaks down?

Yes, we provide fast technical support and maintenance services.

What safety features do your filling machines have?

Our machines have emergency stop buttons, safety guards, and other safety measures to protect operators.