Filling Machines Company in Riyadh

Filling Machines Company in Riyadh, Saudi Arabia

Ideas Packaging Machinery stands as a trusted filling machines filling machines company in Riyadh, Saudi Arabia, with over 25 years of expertise in packaging machinery production lines. We specialize in delivering advanced filling solutions for various industries, offering machines for coolant, brake fluid, detergent, corrosive liquids, grease, carbonate drinks, juices, and lubricants. Designed to ensure efficiency and precision, our machines cater to diverse production needs while maintaining top-notch quality and performance.

With a strong focus on reliability and innovation, Ideas Packaging Machinery provides seamless integration into your production line, minimizing downtime and maximizing output. Choose us for comprehensive support, customized solutions, and cutting-edge technology to enhance your business efficiency and meet your operational goals with confidence.

Types of Filling Machines Available

Gravity Filling Machines

Perfect for light, free-flowing liquids like water and wine.

Piston Filling Machines

Ideal for dense and heavy products like creams and sauces.

Overflow Filling Machines

Maintains uniform fill levels for foamy liquids like shampoos and cleaners.

Vacuum Filling Machines

Ideal for glass containers used for liquids, such as perfumes and solvents.

Pump Filling Machines

Ideal for various liquids such as oils and lotions.

Net Weight Filling Machines

Fills according to the product's weight, typically used for bulk items like detergents and chemicals.

Auger Filling Machines

Used for dry ingredients and granular materials (e.g., flour, spices).

Flow Meter Filling Machines

Monitors flow to ensure precise volume, ideal for high-value liquids such as pharmaceuticals and oils.

Rotary Filling Machines

Ideal for fast-paced production, it is commonly used in the beverage industry.

Aseptic Filling Machines

Created for hygienic products such as dairy and pharmaceutical liquids.

Advantages of Our Tailor-Made Filling Machines

Experience the advantages of our custom-made filling machines, designed to suit your needs perfectly. These machines enhance efficiency with precise, consistent filling, reducing waste and operational costs. Tailored to fit your specific requirements, they integrate seamlessly into your production line, boosting overall productivity. Our machines are built for durability and reliability, ensuring long-lasting performance with minimal downtime. Additionally, we offer dedicated support and maintenance to keep your equipment running smoothly. Choose our custom-filling solutions to elevate your operations with advanced technology and exceptional service.

Premier Global Supplier of Filling Machines

Ideas Packaging leads the global market in providing top-tier filling machines that redefine industry standards. Our advanced machines are expertly designed for maximum precision, efficiency, and durability, catering to a wide range of industries, such as food, beverage, pharmaceuticals, and cosmetics. We are committed to offering innovative solutions tailored to your specific needs, ensuring seamless operations and enhanced productivity. By partnering with us, you gain access to cutting-edge technology and reliable after-sales support. Let Ideas Packaging elevate your production line with filling machines that deliver superior performance, reliability, and consistent results. Choose us to drive your business toward success.

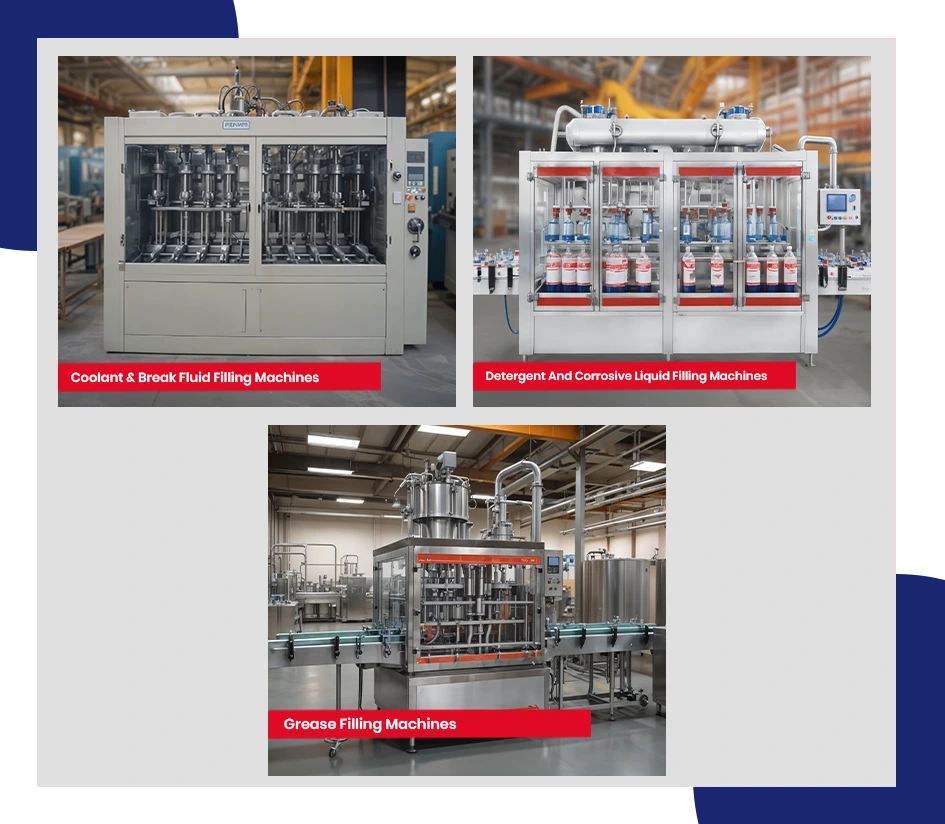

Coolant & Break Fluid Filling Machine

Boost your production with our advanced Coolant and Brake Fluid Filling Machine. Built for precision and speed, these machines guarantee accurate, waste-free filling, enhancing efficiency and dependability in automotive and industrial applications. Optimize your processes using cutting-edge technology that streamlines operations and elevates performance.

Detergent And Corrosive Liquid Filling Machine

Transform your operations with our advanced Detergent and Corrosive Liquid Filling Machine. Crafted for precision and durability, these machines efficiently manage harsh chemicals, ensuring reliable and accurate filling. By integrating these systems, you’ll enhance both safety and productivity, streamlining your production line while maintaining high standards of efficiency.

Grease Filling Machine

Boost your production with our cutting-edge Grease-Filling Machine. Designed for accuracy and long-lasting performance, these machines provide reliable, consistent filling of thick greases. Enhance your efficiency with our innovative technology, ensuring optimal performance in every batch. Experience unmatched dependability and precision, transforming your production line’s capabilities.

Carbonated Filling Machine (CSD)

Elevate your production with our user-friendly Carbonated Filling Machine (CSD). Built for precision and durability, it ensures perfect fills even with carbonated drinks. This machine reduces spills and errors, enhancing efficiency and safety. Streamline your operations, boost productivity, and keep your factory running smoothly with reliable performance.

Juice Filling Machine

Boost your manufacturing process with our intuitive Juice Filling Machine. Designed for high accuracy and consistency, it fills bottles precisely, even with challenging liquids. This advanced system minimizes spills and errors, improving both safety and productivity. Enhance your operation’s efficiency and streamline your assembly line with reliable performance.

Lubricant Filling Machine

Our Lubricant Filling Machine provide precise and efficient performance, expertly designed to manage different lubricant types. Thanks to advanced technology, these machines ensure accurate fills, cutting waste and boosting productivity. Perfect for various industries, they are simple to maintain and deliver consistent, high-quality results for maximum performance.

Leading Global Supplier of Filling Machines

Setup and After-Sales Service

At Ideas Packaging and Machinery, we ensure that the setup of your filling machines is quick and hassle-free. Our skilled team manages everything from installation to testing, ensuring your equipment operates flawlessly. After setup, we offer dependable after-sales service to keep your machines running smoothly. This includes regular maintenance, prompt troubleshooting, and speedy repairs to reduce downtime. We are dedicated to supporting your success with efficient and friendly service. Choose Ideas Packaging and Machinery for expert setup and continuous support that keeps your operations running efficiently and without interruptions.

What are the most important factors you consider when choosing packaging machinery for your business?

At Ideas Packaging Machinery LLC, we recognize the crucial impact that packaging machines have on the efficiency of your business operations. We are dedicated to providing exceptional packaging solutions that meet and surpass your expectations.

Quality & Durability

Our machines are designed for consistent performance, employing premium materials and precise engineering to reduce downtime and enhance the durability of your investment.

Technology & Innovation

Stay at the forefront with our Next Generation Machines , as Ideas Packaging harnesses the latest technology to enhance efficiency, productivity, and ongoing advancement.

Solutions & Flexibility

We provide custom machines tailored to your packaging needs, accommodating various products while ensuring full production control.

Efficiency & Speed

Our custom machines efficiently handle high-volume production, delivering quick, quality packaging to maximize output.

Design & Maintenance

Our machines provide simple controls and low maintenance, ensuring smooth and reliable production.

After-Sales Support

At Ideas Packaging, we ensure customer satisfaction by providing prompt after-sales support, spare parts, technical assistance, and routine maintenance.

Safety & Standards

At Ideas Packaging, we prioritize customer satisfaction with fast after-sales support, while our machines ensure safety and full compliance with industry standards.

Competitive Pricing

We offer high quality machines at competitive prices, delivering excellent value by lowering long-term costs and enhancing production efficiency.

10 Benefits of Filling Machines

Enhanced Efficiency

Our machines streamline production flow, enable faster, more consistent packaging, and significantly increase output.

Cost Reduction

Automation lowers labour costs, reduces packaging errors through precise and consistent packaging, and minimizes waste, saving businesses money.

Customizable Solutions

Our machines are not one-size-fits-all. They are tailored to fit your unique production needs, ensuring a perfect fit for your specific product types and processes.

Durability and Reliability

Built with best quality materials and genuine parts, our machines ensure long-term use, reducing downtime and maintenance costs.

Precision and Consistency

Every machine provides uniform packaging, enhancing product quality and maintaining brand consistency.

Scalability

As your business expands, our packaging solutions can quickly scale, increasing production capacity without delays.

Compliance

All our machines meet global standards like FDA, CE, and GMP, ensuring market compliance.

Environmentally Friendly

Our machines feature energy-efficient designs, such as automated power-saving modes and low-energy consumption motors, helping businesses reduce their environmental impact.

Support and Training

We offer ongoing support and training to ensure your team operates the machines efficiently and resolves issues quickly.

Advanced Technology

Our cutting-edge solutions, including automation and robotics, future-proof your packaging operations and keep you competitive globally.

10 Key Things to Consider Before Buying Filling Machines for Your Production Line.

If you are setting up a production line or upgrading your existing one, choosing the right filling machine is a big decision. Filling machines are essential for packaging products like liquids, powders, or creams. They help ensure that your product is filled into containers quickly and accurately. But how do you know which filling machine is the best for your business?

Frequently Asked Questions (FAQ)

Explore our FAQ section for quick answers. We provide helpful insights, guide you through options, and ensure clarity.

What types of filling machines do you offer?

We offer a wide range, including liquid, semi-automatic, automatic, and specialized machines for various products like liquids, creams, and pastes.

How do I know which filling machine is right for my business?

Our team helps evaluate your specific needs and recommends the best machine for your production volume, product type, and budget.

Are your filling machines customizable?

Yes, we offer tailored solutions, ensuring our machines meet your exact requirements for accuracy, speed, and efficiency.

How reliable are your filling machines?

Our machines are built with durability in mind, using high-quality materials to ensure long-lasting and consistent performance in demanding environments.

Do you offer maintenance services for filling machines?

Absolutely! We provide expert maintenance services to keep your equipment running smoothly and reduce downtime.

Can your machines handle different types of liquids?

Yes, our machines can handle a wide variety of liquids, including oils, juices, creams, and corrosive liquids, ensuring optimal results.

How easy is it to operate the filling machines?

Our machines are designed for user-friendliness, with simple controls and clear instructions, ensuring easy operation by your team.

What is the speed of your filling machines?

Our machines offer various speeds depending on your production needs, ensuring efficient filling and improved throughput.

Can I get a demo before purchasing?

Yes, we provide live demonstrations and trials, so you can see how our machines work and assess their fit for your production line.

What are the safety features of your filling machines?

Our machines are equipped with multiple safety features, including emergency stop buttons, leak detection systems, and protective guards to ensure a safe working environment.